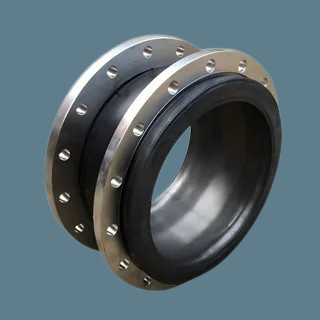

Rubber Bellow

All types of Industrial Expansion Joint and Rubber Bellow manufacturers with Flange

Available Bellow size upto I.D. 4000 mm. & Temperature 400 Degree

Introduction to Rubber Bellow :

Rubber bellow is flexible, bell-shaped components made primarily from rubber or elastomeric materials, designed to accommodate movement while providing protection to mechanical parts. These structures are highly versatile and play an essential role across various industries, including automotive, manufacturing, and construction. Their primary function is to seal and protect sensitive components from environmental hazards such as dirt, dust, and contaminants, which can compromise performance and lead to premature wear.

The design of rubber bellow allows for significant movement, which is particularly beneficial in applications that involve axial, radial, or angular displacements. By maintaining a barrier against harmful external elements, these components contribute to the longevity and reliability of the machinery. In the automotive sector, for instance, Rubber Bellow is commonly used to protect steering and suspension systems, ensuring that critical parts can operate smoothly despite the challenges posed by varying road conditions.

In manufacturing, the importance of Rubber Bellow is equally notable. They safeguard equipment such as hydraulic cylinders and pneumatic actuators, maintaining operational integrity by preventing the entry of debris. Furthermore, their adaptability makes them suitable for various other applications, such as protecting wiring harnesses and pneumatic tubing. The construction industry also utilizes Rubber Bellow for sealing joints and expansion gaps, providing essential flexibility while ensuring a robust barrier against environmental factors.

Overall, Rubber Bellow is vital components that facilitate movement while offering necessary protection in demanding environments. Understanding their applications and significance is crucial for professionals aiming to enhance the performance and durability of equipment in diverse sectors. As industries continue to evolve, the demand for Rubber Bellow is expected to rise, underscoring their importance in modern engineering solutions.

Types of Rubber Bellow :

Rubber Bellow is versatile components utilized across various industries due to their ability to provide protection and flexibility in numerous applications. They can be classified based on their design and material composition, allowing for targeted usage based on the requirements of specific situations.

One of the primary designs of Rubber Bellow is the accordion-style. These bellows are characterized by their pleated structure, which allows for significant axial movement. Accordion-style bellows are commonly employed in automotive applications, such as protecting steering shafts and gear mechanisms from dirt and debris. Their flexibility and compression resistance make them ideal for applications requiring a considerable range of motion.

Another design is the conical Rubber Bellow, which taper from a wider opening to a narrower end. This design promotes efficient sealing while accommodating slight misalignment. Conical bellows are often used in mechanical engineering, where they protect shaft components and provide a seal against contaminants. Their shape makes them particularly effective in situations where space is constrained.

In terms of material composition, natural Rubber Bellow is favored for their excellent elasticity and tensile strength. They are commonly used in applications involving low temperatures or where specific chemical resistance is not a critical factor. However, when enhanced durability and weather resistance are required, synthetic materials such as neoprene or silicone are preferred. Neoprene bellows exhibit superior resistance to oils and varying temperatures, making them suitable for industrial applications. Silicone bellows, on the other hand, are known for their high-temperature resistance and flexibility, making them ideal for use in environments experiencing significant thermal variation.

The choice of Rubber Bellow be it accordion-style, conical, natural rubber, neoprene, or silicone—depends on the specific application and the environmental conditions they are expected to endure. Understanding these types enhances the ability to select the most appropriate component for optimal performance.

Materials used in Rubber Bellow construction :

Rubber Bellow is essential components used in a wide range of applications, providing protection and sealing capabilities in dynamic environments. The choice of material for Rubber Bellow is crucial, as it directly influences their performance characteristics, including durability, flexibility, temperature resistance, and chemical resistance. Several types of rubber materials are commonly employed in the construction of bellows, each offering distinct properties suited for specific applications.

Natural rubber, known for its outstanding elasticity and flexibility, is often used in general-purpose applications. However, its performance may be limited in high-temperature environments, where synthetic alternatives excel. Neoprene, for example, shows great resilience against aging and environmental factors, making it ideal for outdoor applications subject to UV light exposure. Similarly, EPDM rubber possesses excellent resistance to extreme temperatures as well as ozone, which is particularly beneficial in automotive and industrial applications.

For applications involving exposure to various chemicals, materials such as nitrile rubber (Buna-N) or fluorocarbon rubber (Viton) may be preferred. Nitrile rubber is known for its superior resistance to petroleum-based fluids and excellent wear properties, rendering it suitable for oil and gas industries. In contrast, fluorocarbon rubber provides exceptional heat and chemical resistance, making it a prime choice for high-performance applications in the aerospace and pharmaceutical sectors.

When selecting materials for Rubber Bellow, it is imperative to consider the specific application requirements, including operational temperature ranges, potential chemical exposure, and mechanical stresses. Durability, flexibility, and the ability to maintain sealing properties over time should be prioritized to ensure reliability and performance. Ultimately, a thorough understanding of material properties aids in making informed decisions, resulting in the optimal functionality of Rubber Bellow in their respective roles.

Applications of Rubber Bellow :

Rubber Bellow serve a versatile purpose across multiple industries, acting as essential components in various mechanical systems. Their adaptability and resilience make them suitable for a broad array of applications, particularly in the automotive sector. For instance, Rubber Bellow is crucial in automotive exhaust systems, where they accommodate movement caused by engine vibrations and thermal expansion. Additionally, they are utilized in steering mechanisms to protect both the joints and internal components from contaminants, thus enhancing longevity and performance.

In the realm of machinery, Rubber Bellow is employed in a variety of functions such as dust and moisture sealing to protect sensitive internal parts from degrading environmental factors. These components ensure that machinery operates efficiently by preventing dust, dirt, and other contaminants from entering critical areas. Their flexibility allows for smooth movement while maintaining a protective barrier, ultimately prolonging the lifespan of industrial equipment.

Aerospace applications also leverage the advantages of Rubber Bellow. In this fast-paced and demanding field, these components are used in systems that require reliable performance under extreme conditions, such as vibration damping and thermal insulation. By absorbing vibrations and thermal fluctuations, Rubber Bellow play a significant role in enhancing the stability and reliability of aircraft systems, ensuring passenger safety and comfort.

Finally, consumer products also benefit from the incorporation of Rubber Bellow. These components can be found in various household appliances and equipment, where they serve functions such as creating seals or facilitating movement. Their ability to provide cushioning and protection contributes not only to the durability of products but also to their operational efficiency. The widespread use of Rubber Bellow across different industries exemplifies their integral role in modern mechanical systems, showcasing their significance and versatility.

Benefits of utilizing Rubber Bellow :

Rubber Bellow serve a multitude of functions across various industries, offering significant advantages in multiple applications. One of the primary benefits is their ability to protect essential components from environmental factors. Exposure to dust, moisture, and chemicals can lead to premature failure of machinery and equipment. Rubber Bellow create a robust barrier, preventing contamination and ensuring that the internal parts remain clean and functional. This protection is crucial in industries such as automotive and manufacturing, where durability and reliability are paramount.

Another key advantage of Rubber Bellow is their capability to reduce wear and tear on mechanical systems. As flexing and movement occur, components are subjected to friction that can lead to degradation over time. Rubber Bellow mitigate this issue by absorbing shock and creating a cushioning effect that allows for smoother movements. The enhanced flexibility and resilience of rubber decrease the stress on components, effectively prolonging their lifespan and reducing the need for frequent replacements.

Moreover, Rubber Bellow is essential for vibration absorption. Vibrations can compromise the performance of interconnected systems, leading to inefficiencies and potential failure. By incorporating Rubber Bellow, industries can dampen vibrations, thus maintaining the integrity and functionality of machinery. This is particularly important in sectors where precision is vital, such as in aerospace and electronics.

Finally, Rubber Bellow assist in maintaining proper sealing within various applications. This function is critical in preventing leaks of fluids and gases, which can be disastrous in settings such as hydraulic and pneumatic systems. The ability of Rubber Bellow to form a tight seal ensures that operations run smoothly while minimizing the risk of loss or contamination. Overall, the advantages of Rubber Bellow, including environmental protection, reduced wear, vibration dampening, and effective sealing, make them invaluable components in numerous sectors.

Challenges and limitations of Rubber Bellow :

Rubber Bellow, while widely utilized for various applications, present certain challenges and limitations that users must consider diligently. One primary issue is wear and tear over time. Continuous flexing, compression, and extension of Rubber Bellow can lead to material fatigue, causing cracks and eventual failure. This degradation can occur faster in high-stress environments where the bellows are subjected to extreme mechanical loads. As a result, regular inspection and timely replacement become crucial to ensure the longevity of the Rubber Bellow and prevent potential operational failures.

Another significant concern revolves around the susceptibility of rubber materials to environmental degradation. Exposure to harsh chemicals, ultraviolet (UV) light, or ozone can weaken the integrity of Rubber Bellow, resulting in reduced performance. Each of these elements can lead to accelerated deterioration, influencing the bellows’ flexibility and resilience. Thus, selecting the appropriate material based on the specific environmental conditions is vital to mitigate these risks. For instance, specialized rubber formulations can enhance chemical resistance, thereby prolonging service life in demanding settings.

Additionally, Rubber Bellow have limitations in their performance under extreme temperatures. While some rubber types can withstand moderate temperature variance, they may struggle to perform efficiently in very high or low conditions. High temperatures can cause the rubber to harden, leading to brittleness, while low temperatures can result in stiffness and cracking. Consequently, careful consideration of the operational temperature range is essential when selecting Rubber Bellow for specific applications to avoid failures that could lead to costly down times.

In light of these challenges, it is essential for users to evaluate their specific needs thoroughly and consider these limitations when implementing Rubber Bellow in their systems.

Installation and maintenance tips for Rubber Bellow :

Proper installation of Rubber Bellow is crucial for ensuring their longevity and functionality. One of the primary best practices involves selecting the appropriate bellows for the specific application. Factors such as the operating environment, temperature range, and intended movement types should guide this selection process. Before installation, it is essential to inspect the Rubber Bellow for any signs of damage or defects as this can affect performance. Ensure that the installation surface is clean and free from debris, which can lead to improper sealing and premature wear.

During the installation, take care not to overstretch the Rubber Bellow, as this can compromise their structural integrity. Using suitable clamps or fasteners is essential to secure the bellows without pinching or damaging them. Additionally, aligning the bellows correctly with adjacent components can prevent unnecessary stress during operation. It’s also advisable to refer to the manufacturer’s guidelines, as they often provide specific recommendations tailored to the particular product.

Maintenance plays a significant role in the performance and lifespan of Rubber Bellow. Regular inspections should be conducted to check for signs of wear, such as cracking, tearing, or loss of elasticity. It is important to clean the surface of the bellows periodically to remove contaminants that can contribute to deterioration. Using mild detergents and warm water is generally safe for cleaning, but always consult the product specifications for suitable cleaning agents.

Common issues that may arise during maintenance include fluid ingress, which can lead to swelling and degradation of the rubber material. It is crucial to monitor the operating conditions to prevent exposure to substances that could harm the rubber. Furthermore, ensuring that the bellows are not subjected to excessive mechanical stress will mitigate premature failures. By following these installation and maintenance tips, the performance and reliability of Rubber Bellow can be significantly enhanced.

Future trends in Rubber Bellow technology :

The landscape of Rubber Bellow technology is rapidly evolving as new materials and design principles come into play. Innovations in polymer chemistry have led to the development of advanced elastomers that not only enhance durability but also improve performance under extreme conditions. For instance, thermoplastic elastomers have gained traction due to their superior flexibility and resistance to wear, making them suitable for applications where traditional rubber might fail. This trend underscores a broader movement towards materials that can withstand harsher environments while maintaining functionality.

Moreover, advancements in design methodologies, particularly the integration of computer-aided design (CAD) and finite element analysis (FEA), allow for the optimization of bellows geometry. This optimization can result in improved pressure resistance and a reduction in manufacturing costs. Many industries are seeking custom solutions that address specific operational challenges, and this demand is driving innovation in the design of Rubber Bellow. The ability to rapidly prototype and test designs using simulation technology is reshaping traditional manufacturing paradigms.

In addition to material and design innovations, there is an increasing reliance on Rubber Bellow in emerging technologies such as robotics, aerospace, and renewable energy systems. Their role in providing protective barriers, vibration dampening, and flexible connections is becoming indispensable. As industries push towards automation and energy efficiency, Rubber Bellow is being incorporated into systems where space and weight considerations are paramount. The adaptability of these components is paving the way for further integration into advanced applications, such as electric vehicles and smart manufacturing setups.

Overall, the future of Rubber Bellow technology is bright, with continuous improvements expected in materials, design, and application. The ability to meet the evolving demands of various industries while maintaining the essential qualities of flexibility and resilience will be crucial in driving the next phase of development for Rubber Bellow.

What is a Flange in Rubber Bellow and it’s importance :

A flange is a mechanical component that acts as a barrier or connection point for various systems, typically utilized to join two separate parts, such as pipes or fittings. It is designed in a way that allows easy assembly and disassembly without requiring extensive labor or tools. Flange come in myriad shapes and sizes, tailoring them for specific applications and environments. The most common types include weld neck, slip-on, threaded, and blind flange, each offering unique benefits depending on the operational requirements.

The importance of flange can be seen in their ability to provide a reliable and robust connection between two components. By forming a tight seal, flange help maintain the integrity of the system, preventing leaks or failures that could compromise performance or safety. This is particularly crucial in applications that require stringent containment measures, such as fluid or gas transfer systems. The material and design of the flange significantly influence the performance of the connection, determining aspects such as pressure resistance and thermal stability.

In systems employing Rubber Bellow, flange play an essential role in securing the bellows to other components. Rubber Bellow, designed to absorb movement and vibration, benefit from the secure connections that flange provide. The flanged connection not only enhances the durability of the installation but also ensures a leak-proof connection, reducing the risk of contamination or failure. Applying the appropriate flange type, which matches the specifications of the Rubber Bellow, helps optimize the overall performance of the system while ensuring extended service life.

Applications of Rubber Bellow with Flange :

Rubber bellow with flange serve a critical role in various industries, providing effective solutions for dynamic sealing, shock absorption, and flexibility. One of the most prominent sectors utilizing these components is the automotive industry. In vehicles, Rubber Bellow with flange assist in isolating engine vibrations, protecting sensitive components from dirt and moisture ingress, and ensuring the smooth transition of fluids through the system. Their adaptability to diverse temperatures and pressures makes them essential in both passenger and commercial vehicles.

The aerospace industry also relies on Rubber Bellow with flange, particularly in applications where movement and temperature fluctuation are prevalent. These components are employed to create airtight seals on fuel tanks, hydraulic systems, and cabin pressurization systems. The lightweight yet durable nature of Rubber Bellow contributes to increased efficiency in aircraft design while maintaining safety standards during operation.

In the manufacturing sector, Rubber Bellow with flange is integral to machinery that requires isolation from contaminants and dynamic movement. They are often used in CNC machines, conveyor systems, and robotic arms to ensure smooth operation while minimizing wear and tear on components. Their installation can significantly enhance the reliability and lifespan of machinery, making them a wise investment for manufacturing firms looking to optimize productivity.

Another notable application can be found within piping systems, where Rubber Bellow with flange facilitate the efficient transfer of liquids and gases. They provide necessary flexibility to accommodate thermal expansion or contraction, while also absorbing shocks from pipeline vibrations. In essence, these bellows assist in maintaining the integrity and efficiency of piping systems across various industries, highlighting their versatile application in modern engineering.

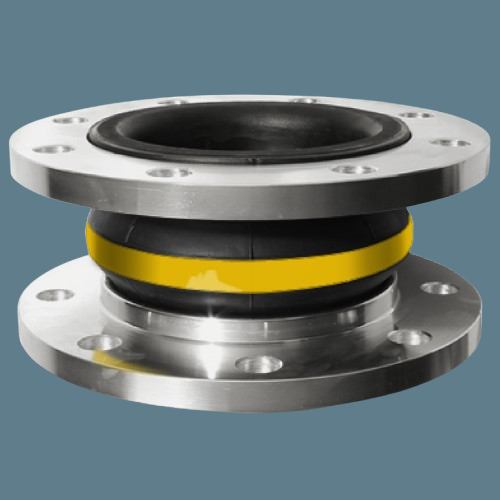

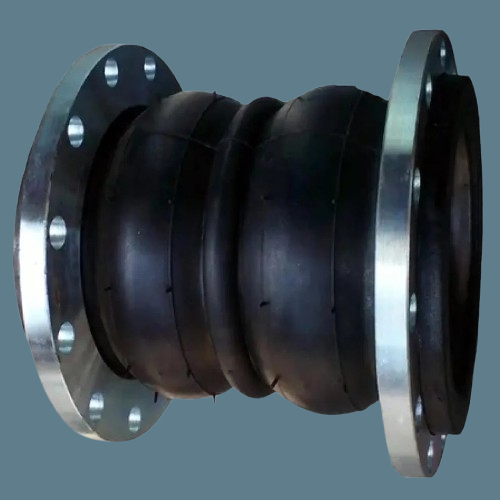

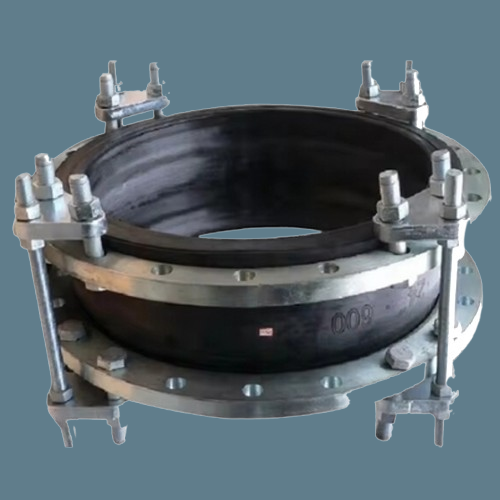

Types of Rubber Bellow with Flange :

Rubber bellow with flange is essential components utilized in various industrial applications. They come in several types, each uniquely designed to meet specific needs. Understanding these categories is crucial for selecting the right bellows for a particular application.

One prominent category is the compression bellows. These bellows are designed to absorb axial movement and compress as necessary, making them ideal for dynamic applications. Compression bellows typically feature a flexible structure which enables them to withstand vibrations and changes in temperature, thus providing protection for adjacent components. They are commonly used in automotive applications, machinery, and robotics, where they facilitate movement while preventing dust and moisture infiltration.

Another significant type is the expansion bellows. Designed to absorb and accommodate movements due to thermal expansion or contraction, these bellows serve essential functions in piping systems. Expansion bellows help to prevent stresses within the system by allowing for longitudinal, lateral, or angular movements. They are especially beneficial in environments where temperature fluctuations are frequent, such as in HVAC systems and chemical processing plants.

Customized bellows represent another important variation. These bellows are crafted to meet specific operational demands and dimensions that standard options may not fulfill. Customization may include material selection, size adjustments, and unique design features. They find applications in specialized fields such as aerospace, pharmaceuticals, and food processing, where precise specifications are necessary for optimal performance.

In summary, understanding the various types of Rubber Bellow with flange is fundamental for their effective application. Compression and expansion bellows cater to different movement types, while customized bellows provide tailored solutions for unique requirements. Assessing the specific needs of your application can guide the selection process, ensuring optimal performance and longevity of the equipment in use.

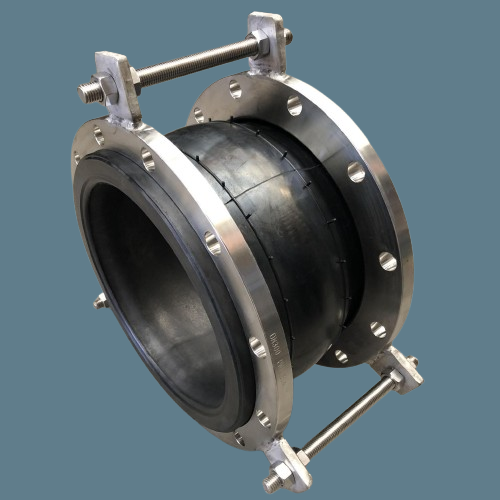

Advantages of using Rubber Bellow with Flange :

Rubber bellow with flange offer a myriad of advantages that make them a preferred choice in various industrial applications. One of the primary benefits is their inherent flexibility. This flexibility allows Rubber Bellow to accommodate fluctuations in movement and vibration, which is crucial in systems where misalignment might occur. For instance, in piping systems, Rubber Bellow can effectively absorb the thermal expansion or contraction, ensuring structural integrity and longevity.

Another significant advantage is their resistance to chemical corrosion. Rubber is naturally resilient against a variety of chemicals and environmental factors, making these bellows highly durable, even in harsh conditions. For example, in wastewater treatment facilities, Rubber Bellow can withstand corrosive substances, thereby reducing the risk of failure and prolonging maintenance intervals. This characteristic is essential for industries handling aggressive chemicals, where typical materials might erode quickly.

The ease of installation is another compelling reason to select Rubber Bellow with flange. Their design enables straightforward integration into existing systems, which minimizes downtime during installation. This feature is particularly beneficial in manufacturing plants, where operational continuity is vital. Rather than requiring extensive modifications, Rubber Bellow can be quickly fitted, saving both time and resources.

Furthermore, these components offer a remarkably long service life. The longevity of Rubber Bellow translates to cost savings over time, as they reduce the frequency of replacements and associated labor costs. Industries leveraging these bellows often report enhanced operational efficiency since their equipment runs smoothly without the typical wear and tear associated with rigid joints.

Overall, the advantages of using Rubber Bellow with flange such as flexibility, chemical resistance, ease of installation, and long service life—underscore their critical role in facilitating effective and reliable industrial processes.

Factors to consider when choosing Rubber Bellow with Flange :

When selecting Rubber Bellow with flange, it is essential to evaluate several critical factors to ensure optimal performance and longevity. One primary consideration is material compatibility. Different applications may require specific rubber compounds, such as EPDM, neoprene, or silicone, depending on the substances they will be exposed to. For example, EPDM is suitable for applications involving exposure to UV light and ozone, whereas silicone might be better for high-temperature environments.

Another crucial aspect is size dimensions. Accurate sizing is necessary to ensure that the Rubber Bellow fit properly within the assembly and can accommodate the required movement without strain or restriction. It is advisable to measure both the flange dimensions and the bellows’ length, ensuring that you account for any potential expansion or contraction during operation.

Temperature resistance is also a vital factor to consider. Rubber Bellow with flange is often exposed to varying temperature ranges, and using materials that can withstand high or low temperatures without deforming or failing is imperative. For industrial applications, it’s wise to consult temperature tolerance charts provided by manufacturers to select the appropriate product for the specific environment.

Pressure ratings must be evaluated as well. The Rubber Bellow should be capable of handling the operational pressures within the system. This rating is usually specified by the manufacturer, ensuring that the bellows can function correctly under typical service conditions. Lastly, the environment where the bellows will be used should be assessed. Factors such as exposure to chemicals, moisture levels, and mechanical stresses play a vital role in determining the appropriate type of Rubber Bellow with flange to ensure durability and performance.

Installation and maintenance of Rubber Bellow with Flange :

Rubber bellow with flange is crucial components in various applications, providing flexibility and vibration dampening. Proper installation and maintenance are essential to ensure their optimal performance and longevity. The installation process begins with selecting the appropriate size and type of bellows according to the specifications of the equipment they will be attached to. Before installation, it is important to inspect the bellows for any visible defects such as cracks or tears. If any issues are found, it is advisable to replace the bellows to avoid future complications.

During installation, align the flange accurately to prevent undue stress on the bellows. Use appropriate tools to tighten the flange bolts evenly, ensuring that the torque specifications recommended by the manufacturer are followed. Over-tightening can lead to deformation of the rubber material, while under-tightening can cause leaks. It is also vital to use a gasket or O-ring to create a secure seal, preventing any leakage of fluids or gases. Once installed, conducting a thorough system check is prudent to confirm that there are no leaks and the bellows are functioning as intended.

Maintenance of Rubber Bellow is critical to their longevity. Regular inspections should be scheduled to check for signs of wear, including cracks, abrasions, or degradation due to exposure to extreme temperatures or chemicals. If deterioration is observed, immediate action is necessary, potentially involving replacement. Additionally, it is essential to keep the surrounding area clean and free from debris that could cause damage. Lubricating the surfaces in contact with the bellows can also reduce friction, thereby prolonging their life. By adhering to these best practices, the performance and durability of Rubber Bellow with flange can be significantly enhanced.

Common issues and troubleshooting :

Rubber Bellow with flange is widely used in various industries due to their flexibility and ability to accommodate movement. However, like any mechanical component, they are prone to certain issues that can affect their performance. Understanding these common problems is crucial for effective troubleshooting and maintenance.

One prevalent issue is leakage. Rubber Bellow can develop leaks due to wear, improper installation, or exposure to harsh chemicals. For instance, if the bellows are installed at an angle, the uneven distribution of stress can lead to premature wear, causing leaks. To troubleshoot this, it is important to inspect the installation carefully, ensuring the bellows are aligned correctly. If leaks persist, replacing the bellows may be necessary.

Wear and tear is another significant problem, especially when Rubber Bellow is used in high-movement applications. Over time, the material can degrade, leading to reduced performance. Regular inspections can help identify early signs of wear, such as cracks or bulges in the material. In many cases, preventative measures, such as using protective covers or adjusting the operating conditions, can extend the lifespan of the bellows.

Additionally, failure can occur if the bellows are exposed to extreme temperatures or if they are subjected to excessive pressure. For example, a manufacturing facility might notice bellows failing under thermal stress when used near hot equipment. To resolve this issue, ensuring that the bellows are rated for the specific environmental and operational conditions is essential. Choosing the right material such as silicone for high-temperature applications—can also mitigate the risk of failure.

In addressing these issues, it is advisable to keep detailed maintenance records and perform regular checks. Being proactive allows for timely interventions, ultimately ensuring the longevity and effective operation of Rubber Bellow with flange.

The role of Rubber Bellow manufacturers :

Rubber bellow manufacturers play a crucial role in various industries by supplying high-quality and reliable products that cater to diverse applications. The primary responsibility of these manufacturers is to design, produce, and maintain the integrity of Rubber Bellow, which serve essential functions such as protecting machinery, absorbing vibrations, and providing seals against environmental factors. Ultimately, the effectiveness of Rubber Bellow directly impacts the performance and longevity of the equipment they are used in.

To meet the demands of different industries, rubber bellow manufacturers engage in an iterative design process that considers specific requirements such as size, material composition, and functional performance. This customization ensures that the final products are not only versatile but also tailored to fulfill customer specifications. By leveraging advancements in technology and materials science, these manufacturers can innovate their designs to improve durability and efficiency.

Quality control is another critical responsibility of rubber bellow manufacturers. They need to ensure that their products conform to industry standards, such as ISO and ASTM, which serve to maintain safety and reliability within relevant applications. This process typically includes rigorous testing methods, such as tensile strength tests, pressure tests, and environmental resistance assessments. By adhering to such quality assurance practices, manufacturers can guarantee that their Rubber Bellow is capable of withstanding challenging conditions while delivering optimal performance.

Furthermore, rubber bellow manufacturers must maintain a strong relationship with their suppliers to secure the highest quality raw materials. The selection of these materials is fundamental, as the properties of the rubber used will greatly influence the resilience and functionality of the final product. By fulfilling these responsibilities effectively, rubber bellow manufacturers contribute significantly to the overall success and efficiency of the systems that rely on their bellows.

Selecting the right Rubber Bellow manufacturer :

Choosing the appropriate Rubber Bellow manufacturer is critical for ensuring that the end product meets specific performance and durability requirements. One of the foremost criteria to consider is the manufacturer’s experience in the industry. Manufacturers with a proven track record typically offer a wealth of knowledge and expertise, which can be crucial for meeting unique specifications. It is advisable to seek out manufacturers who specialize in rubber bellow production, as they are likely to have a better understanding of the nuances and complexities involved.

Another important factor is the production capacity of the manufacturer. Assessing whether a manufacturer can handle large orders or bespoke requirements is vital, especially if you anticipate fluctuating demand. This involves understanding the operational capabilities and technological advancements the manufacturer employs, which can directly influence lead times and production efficiency.

Quality certifications also play a significant role in selecting a rubber bellow manufacturer. Certifications such as ISO 9001 demonstrate a commitment to quality management systems. It is prudent to inquire about the various quality control measures implemented during the manufacturing process, as these can help in assuring the reliability of the Rubber Bellow produced.

Evaluating customer reviews and testimonials can provide insight into the manufacturer’s reputation and the actual experiences of previous clients. Satisfied customers often share their experiences regarding product quality, responsiveness, and support. This feedback is essential for making an informed decision.

Lastly, effective communication and aftermarket support should never be underestimated. A manufacturer that prioritizes clear communication will facilitate a smoother production process, while strong after-sales support is vital for addressing any issues or concerns that may arise post-purchase. Keeping these important criteria in mind will enable you to select a manufacturer that aligns with your requirements and expectations.

Quality assurance in Rubber Bellow production :

Quality assurance plays a critical role in the rubber bellow manufacturing process. To produce high-quality products that meet customer requirements, manufacturers implement a variety of rigorous quality assurance practices. One of the primary steps in this process is material testing. Before production begins, raw materials undergo comprehensive evaluation to ensure they possess the necessary properties, such as elasticity, durability, and resistance to environmental factors. This initial phase is crucial, as the quality of the raw materials directly influences the overall performance and longevity of the final product.

Compliance with recognized industry standards, such as ISO and ASTM, also forms the backbone of effective quality assurance in rubber bellow manufacturing. Adhering to these standards not only ensures that products meet the outlined specifications but also serves to build trust with clients. ISO standards, particularly those relating to quality management systems, necessitate that manufacturers regularly assess their operational processes and implement improvements where necessary. Similarly, ASTM standards provide a framework for acceptable levels of performance and reliability, ensuring that Rubber Bellow produced are fit for purpose.

Furthermore, continual monitoring during the production process is essential in identifying potential defects and deviations from the desired specifications. This proactive approach allows manufacturers to address issues in real-time, which minimizes waste and rework costs while maintaining high-quality output. Techniques such as statistical process control (SPC) can be employed, allowing for the analysis of production data to identify trends and variances in quality. Implementing these quality checks throughout the manufacturing stages not only reduces the risk of defects but also enhances customer satisfaction by ensuring that the final products consistently meet or exceed expectations.

Innovations in Rubber Bellow manufacturing :

Recent years have witnessed significant advancements in the rubber bellow manufacturing industry, driven by ongoing innovations in material science, production techniques, and design processes. These enhancements have led to improved performance and durability of Rubber Bellow, making them increasingly effective in various applications across multiple sectors.

One notable innovation is the use of advanced elastomers that provide superior resistance to chemicals, extreme temperatures, and abrasions. For instance, some manufacturers now utilize synthetic rubbers that exhibit enhanced mechanical properties, resulting in bellows that maintain their functionality under demanding conditions. This not only increases the longevity of the products but also decreases the need for frequent replacements, ultimately benefiting end-users.

In terms of production techniques, automation and advanced manufacturing processes have revolutionized the efficiency and precision of rubber bellow fabrication. Companies are increasingly adopting techniques such as 3D printing and additive manufacturing, which allow for the creation of intricate designs with minimal waste. This transition to modern techniques not only reduces production time but also contributes to a lower environmental footprint, aligning with global sustainability goals.

Moreover, the design processes of Rubber Bellow have evolved significantly. Computer-aided design (CAD) software is now routinely employed to analyze and optimize bellow geometry, resulting in products that can better withstand dynamic loads and varied environmental conditions. Manufacturers such as have led this charge, integrating simulation tools to predict performance, ultimately advancing the reliability of Rubber Bellow.

These innovations reflect a broader trend within the rubber bellow manufacturing industry towards increased efficiency, sustainability, and performance. As leading manufacturers continue to push the boundaries of technology, we can expect ongoing improvements that will further enhance the functionality and application range of Rubber Bellow.

Challenges faced by Rubber Bellow manufacturers :

Rubber bellow manufacturers encounter a variety of challenges that can significantly impact their operations and overall performance. One of the primary difficulties is sourcing high-quality materials. The durability and functionality of Rubber Bellow depend largely on the quality of the raw materials used in their production. Manufacturers must establish strong relationships with reliable suppliers to ensure consistent access to high-grade rubber materials. Fluctuations in material availability and quality can jeopardize production schedules and product reliability.

Another challenge faced by these manufacturers is managing production costs. The production of Rubber Bellow requires specialized machinery and skilled labor, leading to higher manufacturing expenses. Manufacturers must continuously evaluate their processes to identify areas where efficiencies can be gained while maintaining the quality of the end products. Achieving a balance between cost reduction and product integrity is crucial, particularly in a highly competitive market.

Additionally, rubber bellow manufacturers must adapt to changing customer demands. As industries evolve, the specifications for Rubber Bellow may shift to accommodate new applications. This demands flexibility in production processes, requiring manufacturers to innovate and modify existing designs quickly without compromising quality. Consumer preferences for sustainability and eco-friendly products also heighten the complexity of meeting changing market needs.

Lastly, adhering to regulatory requirements poses a significant challenge. The rubber industry is subject to various regulations regarding materials and environmental protections. Manufacturers must stay informed about these regulations to maintain compliance while also ensuring that their products meet industry standards. Generating documentation and certifications can be resource-intensive, but it is essential to foster customer trust and marketability.

To address these challenges, Rubber Bellow manufacturers are increasingly investing in research and development, enhancing supply chain management, and adopting advanced manufacturing technologies. By implementing these strategies, they can overcome obstacles and secure a competitive edge in the industry.

Sustainability in Rubber Bellow manufacturing :

Sustainability has become a pivotal focus for industries worldwide, including the rubber bellow manufacturing sector. As environmental concerns grow, manufacturers are increasingly implementing sustainable practices aimed at minimizing their ecological footprint. One significant aspect of these practices is responsible material sourcing. Eco-conscious manufacturers prioritize the use of renewable and recycled materials, thus reducing their reliance on virgin resources. This approach not only alleviates the depletion of natural habitats but also diminishes the energy consumption involved in extracting and processing new materials.

Another critical area of focus in sustainable Rubber Bellow manufacturing is waste management. Innovative manufacturers are adopting strategies that effectively manage, reduce, and recycle waste generated during the production process. This includes reusing scrap rubber and minimizing leftover materials, which not only curtails landfill contributions but also promotes a circular economy. By integrating waste recycling initiatives, manufacturers can transform what was once discarded into valuable resources for future production.

Energy efficiency is also a major consideration in sustainable practices. Rubber Bellow manufacturers are increasingly investing in energy-efficient technologies and renewables, such as solar and wind power, to reduce greenhouse gas emissions associated with their production activities. Additionally, optimizing machinery and production techniques can lead to significant savings in energy consumption, ultimately resulting in lower operational costs and a reduced carbon footprint.

Consumers play a vital role in fostering sustainability within the Rubber Bellow manufacturing industry. By choosing to purchase products from eco-friendly manufacturers, consumers can support sustainable practices and encourage more companies to adopt environmentally responsible strategies. In this era where climate change is a pressing global issue, the collective efforts of manufacturers and consumers are essential in driving the shift towards a more sustainable future.

About us

Royal Engineering Corporation is a leading manufacturer of Rubber Bellow and Expansion Joint with more than 20 years experience. Company is certified with ISO 9001 : 2015 by IAF.