Rubber Bellow

What is a Rubber Bellow ?

A Rubber Bellow is a flexible connector used in piping systems to absorb thermal expansion, contraction and vibration. By allowing movement, this Bellow helps to alleviate stress on piping systems caused by temperature fluctuations or mechanical vibrations. It is designed to accommodate movement and absorb shock, ensuring that the system operates smoothly. The unique design of a Rubber Bellow allows it to expand and contract, which is crucial in applications where components experience motion or vibration. A Rubber Bellow can be defined as a hollow, flexible component made of rubber or elastomeric materials. Its structure typically resembles an accordion, which makes it exceptionally versatile in different environments.

Rubber Bellow types :

Cylindrical : These flexible structures are designed to compensate for movement or misalignment in machinery while providing a reliable seal. Made primarily from durable rubber materials, they are capable of absorbing vibrations and dampening impacts, which enhances the longevity of the connected components. One of the defining characteristics of cylindrical rubber bellows is their ability to expand and contract without losing functionality. Cylindrical rubber bellows are widely utilized across different industries, including automotive, aerospace and manufacturing.

Circular / Round : This type of Rubber Bellow is flexible, tubular components manufactured primarily from rubber or other elastomers. Their circular shape enables them to efficiently contain fluids or gases, making them ideal for various applications in machinery, automotive, and industrial systems. Due to their unique properties, circular rubber bellows are widely used in many fields. They are commonly found in automotive systems, where they help protect essential components from dust and moisture.

Square and Rectangular : Square and rectangular types Rubber bellow is specifically designed to handle various applications with efficiency. The square rubber bellows have equal sides and can conform to corners and edges seamlessly. Both types are engineered for durability, ensuring they withstand a range of environmental conditions while maintaining their shape and functionality. These Bellows are widely used in industries such as automotive, aerospace and manufacturing.

Tapered : This Rubber Bellow type is flexible, hollow components typically made of rubber or elastomer materials. These structures are designed to provide protection and support for various types of mechanical equipment. Their tapered shape allows for movement and compression while maintaining a robust seal. They are commonly used in automotive, aerospace, and industrial applications, making them an essential component in many systems. The primary feature of tapered rubber bellows is their unique profile, which gradually decreases in diameter. In the automotive sector, they are often found in steering systems and suspension to protect sensitive components from debris. In the aerospace field, these bellows are crucial for sealing and protecting mechanisms that experience extreme conditions.

Molded Rubber Bellow : A molded type Rubber Bellow is a flexible component, primarily made from durable rubber materials. It is designed to expand and contract while maintaining a sealed barrier between two areas. Often found in various machinery and automotive industries, these components are critical for absorbing shock, reducing vibration and protecting mechanical parts from environmental factors. Molded rubber bellows are characterized by their unique design which allows for significant movement in multiple directions. They are ideal for applications in automotive engines, industrial machines and even medical equipment.

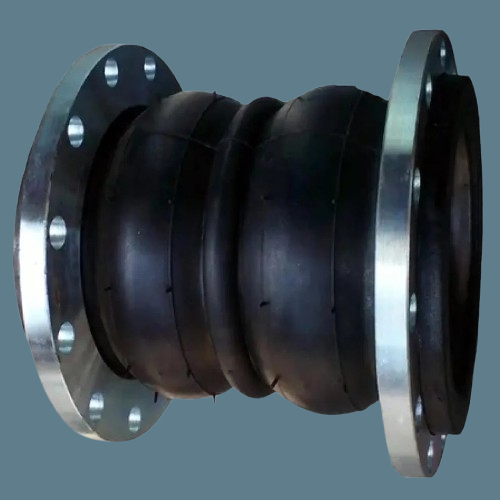

Single Arc : This type of Rubber Bellow is a specialized component used primarily in various industrial applications. It serves as a flexible connector between two parts of machinery, allowing for movement while maintaining a seal against contaminants. This type of Bellow is notable for its unique arc shape, which provides enhanced flexibility and strength under pressure. One of the main advantages of using a single arc type Rubber Bellow is its ability to absorb vibrations and shock while also providing resistance to aging and degradation. They are widely used in the automotive, aerospace and machinery sectors.

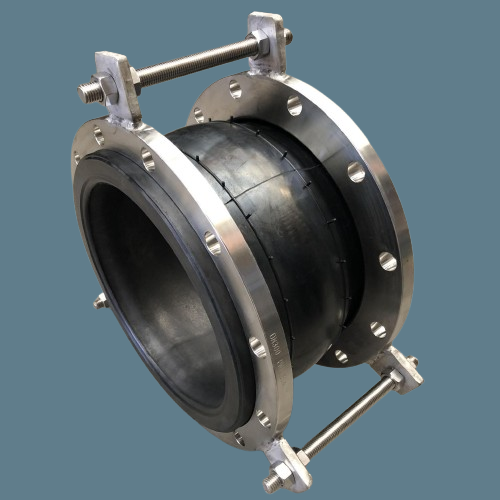

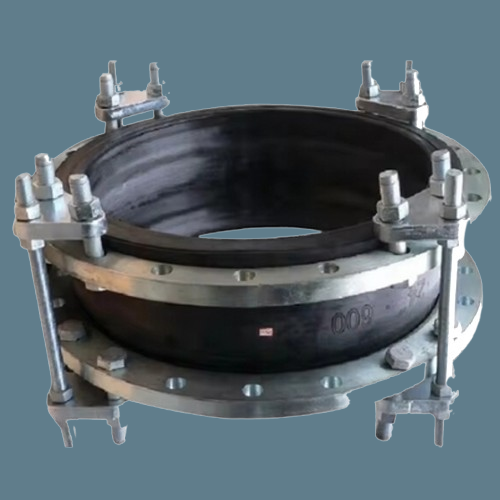

Double Arc : This type of Rubber Bellow is essential components in various engineering applications, particularly in areas requiring flexible connections. A Double Arc Rubber Bellow is a type of flexible joint made from resilient rubber materials. Its design features two arcs that allow for enhanced movement tolerance, making it ideal for use in applications where misalignment or vibration occurs. The unique double arc structure provides greater flexibility compared to traditional single arc bellows, allowing for smoother and more reliable operation. These bellows find extensive use in industries like automotive, aerospace and manufacturing.

Rubber Bellow uses :

In Industrial purposes : One of the primary Rubber Bellows uses is found in industrial machinery, where they function as protective coverings for shafts and rods. They prevent dust, dirt, and moisture from infiltrating critical moving parts, ensuring smooth operation and prolonging lifespan. In addition, these components help maintain proper alignment and absorb vibration, enhancing the efficiency of the machinery.

In Automotive sectors : Rubber Bellow is widely used here for maintaining the integrity of components such as drive shafts and steering systems. They safeguard against the elements, reducing wear and ensuring optimal performance. Their flexibility allows for the necessary movement in these systems, making them indispensable for vehicle operation.

In Steel Plants : One primary reason for the use of Rubber Bellow here for their ability to accommodate movement and misalignment in machinery. This flexibility prevents wear and tear on mechanical parts, ensuring smoother operation and reducing maintenance costs. In steel manufacturing, where heavy equipment is constantly in motion, rubber bellows play a crucial role in sustaining optimal performance. Rubber bellows not only protect against dust and other contaminants but also serve as a buffer against vibrations.

In Cement Plants : Rubber Bellows used and serve multiple functions here. They are primarily used for absorbing vibrations and accommodating movements between connected pipelines or machinery. This adaptability helps to prevent structural damage caused by thermal expansion or shifting loads. They are highly resilient against wear and tear, which is essential given the harsh conditions often found in cement production.

In Petrochemical Refineries : Rubber Bellow is primarily utilized here to connect different segments within piping systems. They effectively handle thermal expansion, vibration and shaft misalignment, ensuring that the system operates efficiently without leaks. They helps in minimizing maintenance costs by preventing leaks and subsequent downtime. The flexibility offered by Rubber Bellow helps in prolonging the life of pumping equipment and pipelines. Their ability to be tailored for specific operational needs makes them a versatile choice for refinery engineers who seek reliability and efficiency in their systems.

In Thermal Power Plants : One significant advantage of Rubber Bellows using in thermal power plants is their durability. Made from high-quality rubber compounds, they exhibit excellent resistance to heat, pressure and corrosive substances commonly found in power generation processes. They also enhance system reliability and safety while ensuring that critical operations run smoothly. Understanding their importance can help plant operators make informed decisions regarding maintenance and upgrades, ultimately improving plant performance.

In Industrial Chimneys : Use of Rubber Bellow in heavy-duty industrial chimneys is vital for ensuring durability, performance and safety. They are not just simple components but rather a critical element that contributes to the overall efficiency of the chimney system. Investing in high-quality Rubber Bellows can lead to longer lifespan and reduced maintenance costs, making them an essential choice for industrial applications.

In heavy duty Water Pipe lines : One of the key benefits of using Rubber Bellow in water pipelines is their ability to prevent leaks. The elastic nature of rubber creates a seal that accommodates movement, thereby reducing the risk of joint failure. Rubber Bellows are resistant to chemicals and corrosion, extending the life’s expectancy of heavy-duty water lines. Heavy-duty water pipelines often experience fluctuations in pressure and temperature. The installation of Rubber Bellow helps to maintain the integrity of the pipeline by allowing for movement during operation. This flexibility is essential in environments where pipes are subject to soil settlement or thermal changes.

In Refineries : The environment often presents multiple challenges, including extreme temperatures and chemical exposure. The use of Rubber Bellows here comes with numerous advantages tailored to refinery operations. Their flexibility allows for thermal expansion, accommodating changes in temperature without risking damage. Additionally, Rubber Bellows are cost-effective solutions that offer long-term savings through reduced maintenance efforts.

Rubber Bellow with Flange :

Both sides metal flanges play a critical role in the functionality of Rubber Bellows. They serve as anchor points that secure the bellow to other components, ensuring a reliable seal between them. The flanges distribute loads evenly, preventing premature wear or deformation, which may occur if the bellow is subjected to uneven stresses.

Having flanges on both ends of a Rubber Bellow ensures stability and alignment during operation. Without them, the bellow may shift or detach, leading to potential leaks and loss of pressure. This can result in decreased efficiency, increased maintenance costs, and even complete system failure.

Moreover, the dual flange design allows for easier installation and replacement, enhancing the longevity of your machinery. Therefore, incorporating both side flanges is not just beneficial but necessary for ensuring optimal performance and reliability of rubber bellows.

Types of Flanges :

- Weld Neck Flanges : These flanges are designed for high-pressure applications, offering strength and stability to the connection.

- Slip-On Flanges : Easy to install, slip-on flanges are ideal for moderate pressure environments and allow for flexibility in alignment.

- Blind Flanges : Used to seal the end of a pipe, blind flanges provide a secure closure, easing the maintenance of rubber bellow systems.

- Threaded Flanges : These flanges have a thread that allows them to connect directly to pipes, making them a versatile option for various configurations.

About Flange materials : Rubber bellow with Flanges are typically constructed from three main materials : Stainless Steel (SS), Mild Steel (MS) and Rubber. Each material offers unique benefits, making them suitable for different applications. Stainless steel flanges are known for their high strength and corrosion resistance. Mild steel provides a cost-effective option with decent strength, suitable for less demanding scenarios. Rubber is often used for the flexible sections of the bellow, enabling the flange to absorb shocks and extend the lifespan of the system.

About Flange Holes : The number of flange holes in a Rubber Bellow is not arbitrary, it’s determined by the bellow size and flange size requirements. The quantity of holes in Rubber Bellow with flange is a vital factor dictated by the Bellow and flange sizes, the extent of vibration and specific user requirements. Properly designed flanges with the correct hole count can significantly enhance system durability and reliability.

About Flange Hole drilling standards : Flange drilling standards are essential in various industries for ensuring compatibility between components, especially when working with Rubber Bellows. Different standards like ANSI/ASME B16.5, DIN (EN 1092-1), JIS and BS provide detailed guidelines on the dimensions and requirements for flanges that integrate rubber sleeves effectively. Each standard caters to specific needs, and understanding these can vastly improve system efficiency and safety.

Types of Flanges are connected with Rubber Bellow : (A) The floating flange offers a unique advantage due to its ability to rotate freely around the rubber collar. This flexibility simplifies alignment during installation, making it one of the most commonly used methods in various industries. The design allows for easier adjustments, which is particularly beneficial when working in tight spaces. (B) The fixed flange is molded or bonded directly to the rubber. Fixed flanges are typically chosen when stability and strength are paramount, particularly in high-pressure systems where leaks would be catastrophic.

Why Flanges are used in Rubber Bellow on both sides : They facilitate both easy installation and removal, ensuring that maintenance and adjustments can be made without hassle. One of the key advantages of using flanges in Rubber Bellows is the secure bolted connection they provide. Flanges are designed to provide a standardized fit with pipeline systems, their compatibility ensures that installation is straightforward, reducing downtime during project setups.

How Rubber Bellow Flanges are fitted with pipelines :

- Check compatibility before installation : Same flange standard (ANSI / DIN / JIS, etc.), Same nominal size (DN / NPS), Correct pressure rating (PN / Class), Rubber material compatible with media and temperature.

- Prepare the pipeline : Shut down and depressurize the system, Clean flange faces (remove rust, debris, oil), Ensure both pipe flanges are properly aligned, Check that bolt holes match.

- Position the Rubber Bellow : Place the rubber expansion joint between the two pipe flanges, Insert bolts through the flange holes, For floating flanges, rotate slightly for easy bolt alignment.

- Insert Bolts correctly : Insert bolts from one side (usually bolt head on fixed side), Use washers if required, Hand-tighten nuts first.

- Bolt direction recommendation : Bolt head toward the rubber side, Nut on the outside.

- Tighten in cross pattern : Tighten gradually in 3–4 stages, Apply uniform torque, Do NOT over-tighten.

- Install Control Rods : Install control rods or limit rods, Prevent over-extension due to pressure thrust.

- Final Inspection : Check alignment, Verify no twisting of rubber, Ensure bolts are evenly torqued.

Rubber Bellow price :

For basic small machinery Rubber Bellows (small sizes), you can expect to see prices ranging from ₹500 to ₹5,000 per piece though depending on the specifications. These smaller sizes are often utilized in applications requiring flexibility and resistance to environmental factors.

When moving on to heavy duty industrial Rubber Bellow used in heavy Pipelines, it’s prices vary significantly with Bellow size (ID & Length), withstand Temp & Pressure and Flanges (made of SS/MS/others). Typically, medium sized Rubber Bellows price range from ₹5,000 to ₹10,000 per piece. For larger, more complex Rubber Bellow cost can escalate significantly, with estimates reaching up to ₹10,000 to ₹80,000 or even more, depending on the intricacy of the unit and required specifications.

Rubber Bellow prices based on dimension : The size of the rubber bellow plays a significant role in its pricing. Specific elements such as diameter, length, and wall thickness contribute to the overall expense. Larger or longer bellows naturally require more material, resulting in higher costs. For instance, a large pipe expansion bellow with a diameter of 500 mm can be significantly more expensive than smaller mechanical bellows. Remember, more material means a higher price tag !

Rubber Bellow prices depends on materials : The type of material used in the production of rubber bellows also greatly affects pricing. Common materials includes : EPDM – Known for good weather and ozone resistance. Neoprene – Offers excellent oil and chemical resistance. Nitrile/Buna-N – Suitable for fuel and oil applications. Silicone – Ideal for high-temperature and food-grade uses.

Rubber Bellow price as per Pressure requirements : Another crucial factor affecting rubber bellow prices is the pressure rating. Bellows designed to withstand higher pressures usually require more robust materials and construction techniques, which can lead to increased costs. Understanding your specific application will help in selecting the right bellow without exceeding your budget.

Rubber Bellow price as per withstand Temperature : The Rubber Bellow prices tends to vary significantly based on their working Temperature resistance capabilities. Bellows designed to endure extreme temperatures often require specialized materials and manufacturing processes. For instance, materials that can withstand high heat or low temperatures generally cost more due to their enhanced properties and durability.

Rubber Bellow prices is depending on order quantity : If a buyer increases the volume of their order, manufacturers can optimize their production processes, thus lowering the cost per unit. Consequently, purchasing larger quantities can yield substantial savings, with each additional bellow becoming cheaper than if purchased in smaller lots. This makes it essential for buyers to consider their order size.